DRUM HANDLING AND LIFTERS EQUIPMENT IN MELBOURNE

Many businesses require that drums be handled with safety in mind from start to finish. That is why at DHE Materials Handling Equipment we deliver safe and reliable lifters, trolleys and other gear to companies throughout Victoria. Regardless of whether the contents of the drum have hazardous material or otherwise, we have the materials that will ensure no one gets harmed in the process. We service companies across Melbourne and nearby cities in Victoria, mainly in the chemical, manufacturing and mining sectors. We are the company to turn to for your drum handling and trolley needs at affordable prices.

Popular Models

The following products are our most requested pieces of equipment which can be delivered to your business in less than 24 hours of order placement.

Container Ramps

Forklift Roll Prong

Fork Spreaders

FORK CAPACITY 5T PLUS Class 4-7 SLIPPERS

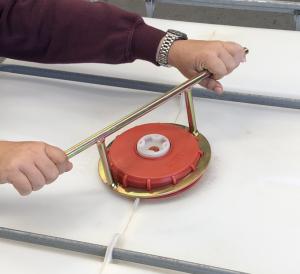

IBC Wrenches

Forklift Cages

Forklift Jibs

Container Ramps

MATERIAL HANDLING EQUIPMENT IN MELBOURNE

DHE Material Handling Equipment takes pride in providing comprehensive, high-quality material handling equipment in Melbourne, Victoria. Our products, which include drum handlers, forklift attachments, container ramps, crane attachments and more, are intended to improve the efficiency and safety of your operations. Whether you require warehouse, manufacturing, or industrial application equipment, our skilled team is committed to providing customised solutions to your unique requirements. Being a trusted manufacturer and supplier of material handling equipment, you can feel the difference in quality and performance that distinguishes us. Contact us today for dependable and long-lasting material handling equipment.

AN AFFORDABLE RANGE OF DRUM TROLLEYS

Our Australian-owned and operated company have been supplying companies with our high-quality equipment for several years. With our time in the industry, we have been able to ensure that our reliable and durable products can store and carry a range of substances. No matter if you are looking for load-bearing trolleys, drums of numerous volumes or lifters that can handle most weight needed, we have the products for you in our online range. We ensure that our products are affordable, yet industry-leading equipment, with our drum trolley and lifter prices being some of the best in Australia. It is important to us that you can rely on our equipment to last throughout the years, which is why they undergo assessments to ensure they meet the safety regulation standards that are set out by the Australian Government. To find out more about our variety of materials handling equipment in Melbourne, get in touch with our team today.

CONTACT OUR MELBOURNE TEAM TODAY

We want to provide you with the products necessary to achieve any job – that is why we have our affordable range of materials handling equipment, including trolleys and drum lifters. To find out more, contact our friendly and professional team today on 1300 067 281, or you can email us at sales@dhemhe.com.au and we’ll get back in touch as soon as possible.

If you need to move drums throughout your factory or warehouse, it could be worth looking through our Drum Handling Archives to make the process easier. We also have a wider range of equipment available, including forklift attachments, container ramps, forklift slippers, spreaders, bin tippers and more.

About Us

The Story

Our Australian-owned and operated company have been supplying companies with our high-quality material-handling equipment for over 20 years. We ensure that our products comply with all the relevant Australian Standards, are well stocked, and at a very competitive price. To find out more about our variety of materials handling equipment in Melbourne, get in touch with our team today.

FAQ

Material handling refers to the movement, protection, storage, and control of materials and products during the manufacturing, warehousing, distribution, consumption, and disposal processes. It includes a wide range of activities and equipment designed to improve efficiency, safety, and productivity when handling materials. Key features of material handling are:

Transportation: The movement of materials between locations utilising machinery such as conveyors, forklifts, and trucks.

Storage: The organised storage of materials on shelves, racks, bins, and containers.

Control: entails managing the flow and tracking of goods through inventory systems and automated solutions.

Protection: Keeping items safe from harm and contamination when handling and storing.

Effective material handling improves workflows, lowers labour costs, reduces the risk of harm, and increases overall operational efficiency.

Material handling equipment refers to a wide range of instruments, vehicles, and devices used to transport, store, regulate, and protect goods during the manufacture, warehousing, distribution, consumption, and disposal processes. Forklifts, pallet jacks, conveyors, cranes, hoists, and other items are among the equipment used. Each piece of equipment is designed to improve efficiency, safety, and productivity when handling and carrying items, resulting in smooth and streamlined operations across a wide range of sectors.

The primary categories of material handling equipment include:

- Storage and Handling Equipment.

Shelves and racks: Used for organised material storage.

Bins & containers: Used to hold and store loose goods.

Drawers and cabinets: Used to store small things and tools.

- Industrial trucks.

Forklifts: Used to lift and transport items.

Pallet Jacks: Used to raise and move pallets manually or electrically.

Order Pickers: Used to retrieve products from high shelves.

Hand trucks and dollies: Used to move big goods manually.

- Bulk Material Handling Equipment.

Conveyors: To transport goods along fixed pathways.

Hoppers and silos: Used to store bulk commodities.

Stackers and Reclaimers: Used to stack and reclaim bulk materials.

- Engineered Systems.

Automated Storage and Retrieval Systems (AS/RS): Used to store and retrieve items automatically.

Robotic Delivery Systems: Used for autonomous material transportation.

Conveyor Systems: Used to move items along a preset path.

Automated Guided Vehicles (AGVs) are designed to deliver materials autonomously.

These categories include the fundamental equipment required to handle, transfer, and store materials efficiently and safely.

Choosing material handling equipment entails numerous important steps:

- Assess Your Needs

Material characteristics include kind, size, weight, and volume.

Handling requirements include processes that include lifting, moving, stacking, and transporting.

- Evaluate the Working Environment

Space constraints: Determine the available space and facility layout.

Operating Conditions: Environmental variables which include temperature and cleanliness.

Workflow: Understand how materials flow through your facility.

- Consider Equipment Features

Capacity and Size: Make sure it can carry the maximum load.

Versatility: Multi-functional equipment that can be used as needed.

Ergonomics: Increase worker safety and comfort.

- Prioritise Safety: Ensure compliance with safety standards and regulations.

Safety features include guards, sensors, and emergency stops.

- Evaluate cost and ROI.

Initial Cost: The purchase price.

Operating costs include maintenance, energy, and downtime.

ROI: Increased efficiency and productivity.

- Vendor and Manufacturer Considerations

Reputation refers to quality and dependability.

Support and Service: Customer assistance and maintenance.

Warranties: Complete warranties and guarantees.

- Future-Proofing: Scalability to expand with your business.

Technology Integration: Compatible with both present and future technology.

When you examine these aspects, you may select equipment that maximises efficiency, safety, and cost-effectiveness.